siman007

New Member

Thank you - just wish I knew what I was looking at

Thank you - just wish I knew what I was looking at

A look inside a Meaco DD8L desiccant dehumidifier. (Which is actually a rebadged You Long YL-208A) These dehumidifiers are much quieter than traditional compressor based ones. They work by rotating a drum of honeycombed desiccant material (zeolite) through an airflow from the area to be dehumidified, then through a heated section that drives the collected moisture out into a condensing panel. I managed to fluff twice and suggest that these units are sensitive to being moved. They aren't. Traditional compressor dehumidifiers are sensitive to being moved during or just before use, since the refrigerant liquid can get into the compressor and stall it.

These units can be dragged out the boot of a car and plugged straight in without a settling time. The desiccant units are very lightweight since they do not contain much metal. Another advantage over the compressor versions is that these ones will operate efficiently down to near zero temperatures when there is virtually no moisture in the air anyway. Compressor units are very inefficient at low temperatures. The reason for the air filter on the front of the unit is to prevent particulate from blocking the pores of the desiccant drum. Although these units consume more power than an equivalent compressor unit with a low setting of typically 300W and a high setting of about 600W they don't use any more power overall since they bring the humidity down quickly and then turn off. The output is a stream of noticeably warm and very dry air. These units are not to be confused with the absolutely useless desiccant dehumidifiers that are either a bag of silica gel or a chemical that absorbs moisture and then turns to slush in a plastic tub. The silica gel is OK for very small enclosed containers but not continuous room dehumidification.

Using a dehumidifier in a home prone to dampness like a coastal home or older style of building will solve many problems like mold and excess condensation on walls and windows. The dryer air is more comfortable and greatly reduces the need to heat the building excessively. Even at it's highest setting (about 600W) one of these units can be run continuously for a full day for considerably less than the cost of a cup of coffee from Starbucks. Most of these units have a laundry setting where wet washing can be hung indoors in the same room as the dehumidifier and it will dry it all quickly by removing the moisture from the air. Although many of these units have quite complex electronic controls, I prefer the simpler version with just a high/low switch and a knob to set the desired humidity. Much simpler and potentially more reliable.

Does anybody know what this is (and where I can get another oneThank you!

Ok I think I now know what it is - I think its a Glass Shell Precision NTC Thermistor - I measured the resistance on the remains of mine at 20c and got 67k ohm which I think equates to the 50Kohm version which has a part no of MF58503F3950 (MF58503F3950 Cantherm | Sensors, Transducers | DigiKey)

hiThanks to the helpful instructions here managed to get mine apart and fix the block that was causing water to leak from it so I took some photos that might help, you can see the puncture holes for the four screws. Plus the the extra bit revealing the extra button.

View attachment 82994

There are four screw for the base (Feet) and the the four screws in the water tank housing.

View attachment 82995

Then as has been said before "unclick" down the sides to get the front panel off.

View attachment 82996

This should give you access to the fan and other motors. I needed to get to the other side so had to undo four more screws.

This one just above the blue wire.

View attachment 82998 View attachment 82999 View attachment 83000 View attachment 83001

Now with the other side off

View attachment 83002

This was actually after I had cleaned the "Crud" blocking the tube poking out the bottom.

I had to remove this bit too

View attachment 83003

Here is the blockage

View attachment 83005

Not sure how helpful this is.

My floor is now dry and and it is all working correctly although the top looks a bit off a mess.

Hey, did you solved your issues? Did they send you a new PCB?I'm also trying to repair a Meaco DD8L Junior which has gone completely dead (no LEDs, no beeps, no fan or motor action). Mine actually has four melt fuses; I first found two green 133° (SEFUSE SF 129E) attached to the back of the heater element enclosure, but both these measured ok so I kept looking and found two brown 99° (SEFUSE SF 96E) fuses on the other side of the desiccator wheel. I had to totally disassemble the unit to get to these, and was dismayed to find that they were also intact. I now have a big pile of parts and no idea what else to look for. Any ideas?

Hi lomax,I have now reassembled the dehumidifier, and have done some probing on the control PCB:

It looks like I might need a new control board, unless anyone has any other suggestions?

- The 1.6A fuse (circled in red in photo) is intact (I had already measured this before disassembly)

- I get continuity on the thermal fuse chain, connected between TC1 and TC (confirming yet again that the thermal fuses are indeed intact)

- The -5V and -12V rails are operating and within tolerance (why negative rails? no idea!)

- There are no signs of life of any kind, even if leads are wiggled or components tapped

I replaced the thermistor with a ntc 50k but the machine is operational only at the low speed fan. Above this the warning light turns on. I think that if the ntc is right must be 100 k if at 25°C the resistance was 67k. Or a ptc of 50 k?I didn't see this post before replying, but yes, that's it. But you really should check if the resistance increases or decreases with temperature, and ideally what it is at another known temperature. Only then can you be sure if it's a PTC (resistance increases with temperature) or NTC (resistance decreases with temperature) thermistor, and precisely which such device (by checking that your two measurements agree with the curve in the datasheet). Boiling water is a reasonable approximation of 100°C (and if you know the current air pressure it can be quite precise).

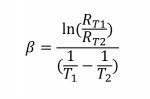

Edit: With those two measurements in hand you can very easily calculate the "beta" value of the thermistor:

View attachment 104562

Where:

Rt1 = Resistance at Temperature 1

Rt2 = Resistance at Temperature 2

T1 = Temperature 1 (K)

T2= Temperature 2 in (K)

Since "beta" is a defining characteristic of thermistors having this value makes selecting the correct one easy.

I replaced the thermistor with a ntc 50k but the machine is operational only at the low speed fan. Above this the warning light turns on. I think that if the ntc is right must be 100 k if at 25°C the resistance was 67k. Or a ptc of 50 k?

I could help check if I knew where the thermistors are located. Or I could measure at different ambient temperatures.I replaced the thermistor with a ntc 50k but the machine is operational only at the low speed fan. Above this the warning light turns on. I think that if the ntc is right must be 100 k if at 25°C the resistance was 67k. Or a ptc of 50 k?

Dear Sir the thermistor is shown clearly at post #105. Now if you touch it with your finger while you measure it the resistance of it must be changing. If it goes upwords is a ptc. If it goes downwards is a ntc.I could help check if I knew where the thermistors are located. Or I could measure at different ambient temperatures.

My ddl has good thermistors ( 115 k ohms at about 20 degs c. But it is dead at front panel, and I dont know how to confirm dead processor or processor type. Have checked supplies on board.

And now I can offer help to some of those with unresponsive microcontrollers..After some days checking various bits of my DD 8L Junior, I suspected the microcontroller chip. To check, I put oscilloscope lead on crystal to see if clock pulses there, and it burst into life. Now fine, so just the oscillator not running without a little tickle.Dear Sir the thermistor is shown clearly at post #105. Now if you touch it with your finger while you measure it the resistance of it must be changing. If it goes upwords is a ptc. If it goes downwards is a ntc.

I made a mistake. The thermistor is shown at post #106.And now I can offer help to some of those with unresponsive microcontrollers..After some days checking various bits of my DD 8L Junior, I suspected the microcontroller chip. To check, I put oscilloscope lead on crystal to see if clock pulses there, and it burst into life. Now fine, so just the oscillator not running without a little tickle.

The oscillator starts by amplifying ambient noise with poditive feedback.

Hope this may help someone..