Rivers & creeks

Well-Known Member

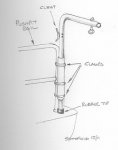

I need to make a simple outboard hoist - it weighs 30kg which is too heavy to lift up from the dinghy below. It lives on a bracket hung off the stern and my plan was to use a piece of stainless tubing, straight for the first 4 feet until it reaches the handrail, then bend it over the next two feet by about 8 inches. Now I'm getting cold feet after researching how difficult it is to bend stainless tube! Am I being a wuss and actually it's not as difficult to do, or is there a simple off the shelf solution? Lots of cheapest davits about but only in pairs and they project outwards far too much.

Thanks.

Sorry I should say I looked at the "easy lift" products and they are either too expensive at almost £400 or not long enough for the cheap model as it needs to be taller than the handrail.

Thanks.

Sorry I should say I looked at the "easy lift" products and they are either too expensive at almost £400 or not long enough for the cheap model as it needs to be taller than the handrail.

Last edited: