West Coast

Well-known member

Hi all, I have a Quick Aleph vertical windlass as common on many AWBs. It has a aluminium upper base which has corroded with some pitting - see photos. I have stripped the windlass down, and will fit new seals and bearings to the aluminium base. Where the vertical shaft comes through the base, there is a lower and upper lip seal, with a ball bearing race in between. The gearbox and motor are in good condition.

There is still sufficient material in the aluminium base to be structurally sound, and i think there is sufficient material to allow the upper lip seal to make good seal contact with the aluminium base. So with new seals and bearings it should still have some further useful life. I am aware I can buy a replacement base but likely this is not cheap.

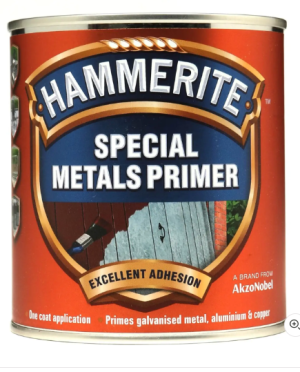

Question - I want to put some form of coating over the corroded aluminium areas before re-assembling to give it some additional protection - can the panel recommend what could be best for this? Aesthetics are not an issue, as all these surfaces are hidden. Checking on line, I see some dichromate type paints, is this the right thing?

Thanks all!

There is still sufficient material in the aluminium base to be structurally sound, and i think there is sufficient material to allow the upper lip seal to make good seal contact with the aluminium base. So with new seals and bearings it should still have some further useful life. I am aware I can buy a replacement base but likely this is not cheap.

Question - I want to put some form of coating over the corroded aluminium areas before re-assembling to give it some additional protection - can the panel recommend what could be best for this? Aesthetics are not an issue, as all these surfaces are hidden. Checking on line, I see some dichromate type paints, is this the right thing?

Thanks all!