GHA

Well-Known Member

I'm not sure if my roller turned with the snubber, since it is something I very seldom did (bridle). I agree with others that a fully threaded rod seems very strange in this application. I was working on mine last week, and it is a smooth bolt with some play at the ends. The roller turns under very light pressure and at high load.

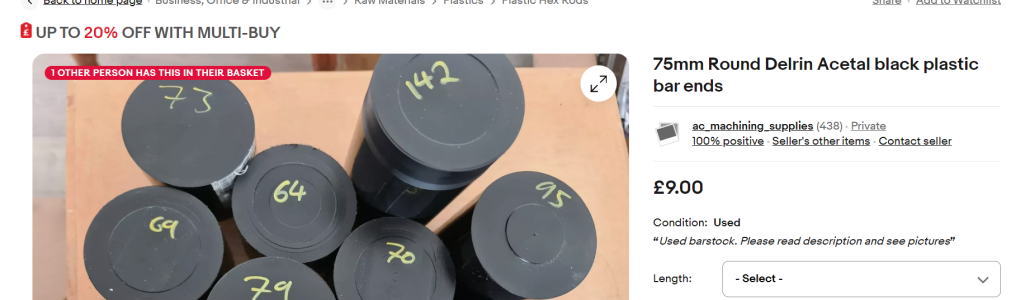

Despite the forum armchair tut tutting back in the real world there is actually very little wear from the rollers running on a threaded bolt shank, much less than I thought which was part of the driver for all this. You can feel the pattern of the thread in the inside of the acetal but still very little play. After what must be about 15 years mostly on the hook since they were fitted. Though they don't actually move much, chain is usually pretty slack getting raised & the onboard snubber is a new addition about a year ago. Quite deep chain link shaped wear on the outside of the chain roller, not a slot any more.

Probably would be fine for another decade, but not right so it will get changed.

The vast majority of the movement comes from onshore winds & a steep chop with the bow pitching up and down a good few feet, the snubber is constantly extending/retracting then sometimes for days. That's a lot of rotation under quite a bit of load.

Up to 35Kts (I've not spent time watching in anything higher) the load is close to constant, boat will tack but it's a gentle affair changing tack, the snubber might extend a fraction as the wind catches the beam afterwards the the stories of boats shooting across anchorages in a stiff wind don't happen on this boat.