niallw70

Active Member

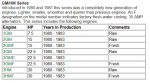

How do I find out the age of my 1gm10, knowing only the engine number 09713. I don't see anything on the Yanmar website to help

On a side note, can anyone recommend a good Yanmar dealer/ repair shop for servicing and ordering spare parts? Hopefully with shop in Central Scotland?

On a side note, can anyone recommend a good Yanmar dealer/ repair shop for servicing and ordering spare parts? Hopefully with shop in Central Scotland?