alahol2

Well-Known Member

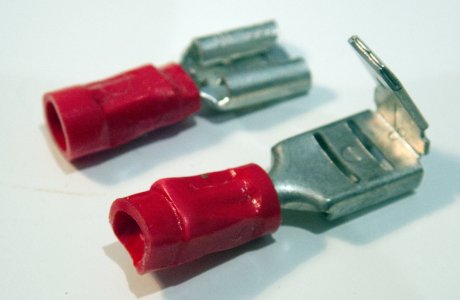

Are you using the crimp terminals that the crimper is designed for? Different dies are required for different terminals. Insulated /non-insulated etc.You cannot make the holes bigger! - well I suppose I could file the teeth down.