Wandering Star

Well-known member

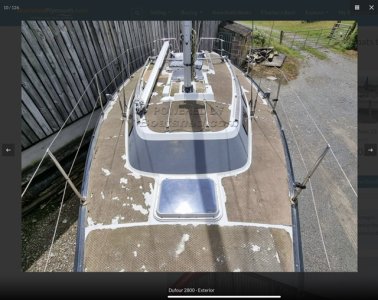

My Dufour 2800 has the decks sheathed with Treadmaster which is in VERY poor condition and i want to strip it all off and then paint the decks. I’ve searched for articles on the easiest way of achieving this and know it’ll be a mammoth task but it has to be done! As a result of my research, I’ve purchased secondhand a Fein Multitool but I still have an eclectic mix of questions before I start …..…

1. The GRP deck under the Treadmaster has a moulded in non slip surface (pimples), once I start stripping the Treadmaster off, will the underlying glue/epoxy/adhesive come off with the Treadmaster covering or will it remain ingrained in between the pimples of the moulded GRP surface In which case how will I clean the residue off?

2. How can identify which type of adhesive was used when the Treadmaster was first laid?

3. What blade should I be using in the Fein Multitool?

4. My boats on a swinging mooring, will a small portable generator (Honda EU 1.0) be powerful enough to run the Fein Multitool? To be honest I wish I’d bought a cordless model but didn’t think it through and too late now!

5. Which deckpaint would you recommend bearing in mind the non slip surface of the GRP.

Any other pieces of advice welcome. For example I wonder if a rotary steel brush head mounted in a grinder would be too brutal for cleaning up the old adhesive prior to painting? In another life I used this method for cleaning the adhesive off a geriatric Westerly deckhead when I replaced the headlining and very effective it was too!

Thanks for any advice - I’m not looking forward to this!

1. The GRP deck under the Treadmaster has a moulded in non slip surface (pimples), once I start stripping the Treadmaster off, will the underlying glue/epoxy/adhesive come off with the Treadmaster covering or will it remain ingrained in between the pimples of the moulded GRP surface In which case how will I clean the residue off?

2. How can identify which type of adhesive was used when the Treadmaster was first laid?

3. What blade should I be using in the Fein Multitool?

4. My boats on a swinging mooring, will a small portable generator (Honda EU 1.0) be powerful enough to run the Fein Multitool? To be honest I wish I’d bought a cordless model but didn’t think it through and too late now!

5. Which deckpaint would you recommend bearing in mind the non slip surface of the GRP.

Any other pieces of advice welcome. For example I wonder if a rotary steel brush head mounted in a grinder would be too brutal for cleaning up the old adhesive prior to painting? In another life I used this method for cleaning the adhesive off a geriatric Westerly deckhead when I replaced the headlining and very effective it was too!

Thanks for any advice - I’m not looking forward to this!

Attachments

Last edited: