William_H

Well-Known Member

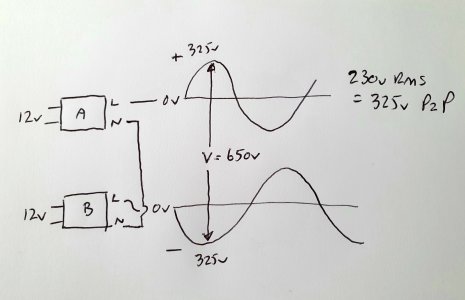

The analogy might be 2x 12v batteries connected in parallel but erroneously connected pos to negative. Thus you have 24v short circuited. Disaster for batteries.

Now AC power swings from peak 325v positive to peak 325v negative. Described as 240v Root Mean Squared.(The effective power is equal to 240v DC)

Now the problem is that an inverter creates it's own timing. Not a problem until you parallel it to another AC source. Some inverters can be timed to an external source. My domestic PV inverter relies on incoming AC for timing so won't provide power without mains connection.

If you can get the positive cycle to coincide with the positive cycle of the other source you have no problems. Assuming frequency is identical.

The problem is that if cycles do not coincide there is a chance that positive cycle on one coincides with negative cycle of the other. Either fully or partially trying to negate the other. Potentially up to 650v short circuited. Most likely less but in any event putting major load on the 2 sources.

Now you might ask how power houses get syncronisation. In the case of a mechanical alternator once syncronised one tends to force the other by varying load to stay in sync. Actual connection can be achieved by finding a time when they are syncronised by measuring voltage difference. Old DC9 jets had 2 alternators 400hzt 115v 3 phase. They had 3 neons on the panel and you wait till the neons go out before switching the second alternator in parallel.

For OP I would stick with one inverter and wear the added losses at low power use. But if he goes for 2 inverters go for separate power outlets for the 2. ol'will

Now AC power swings from peak 325v positive to peak 325v negative. Described as 240v Root Mean Squared.(The effective power is equal to 240v DC)

Now the problem is that an inverter creates it's own timing. Not a problem until you parallel it to another AC source. Some inverters can be timed to an external source. My domestic PV inverter relies on incoming AC for timing so won't provide power without mains connection.

If you can get the positive cycle to coincide with the positive cycle of the other source you have no problems. Assuming frequency is identical.

The problem is that if cycles do not coincide there is a chance that positive cycle on one coincides with negative cycle of the other. Either fully or partially trying to negate the other. Potentially up to 650v short circuited. Most likely less but in any event putting major load on the 2 sources.

Now you might ask how power houses get syncronisation. In the case of a mechanical alternator once syncronised one tends to force the other by varying load to stay in sync. Actual connection can be achieved by finding a time when they are syncronised by measuring voltage difference. Old DC9 jets had 2 alternators 400hzt 115v 3 phase. They had 3 neons on the panel and you wait till the neons go out before switching the second alternator in parallel.

For OP I would stick with one inverter and wear the added losses at low power use. But if he goes for 2 inverters go for separate power outlets for the 2. ol'will