Momac

Well-known member

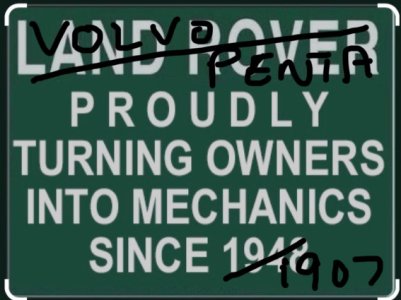

What is the method for removing the bearing pins on a Volvo Penta 290dp-e outdrive? I have removed the locking screws in case anyone was wondering.

I have tried a threaded bar arrangement to jack the pins out but getting nowhere. One pin has budged about 2mm and the other has not moved . I tried tapping the moved pin back in with no success.

I am thinking a slide hammer will not help due to insufficient energy.

I have applied lots of WD40 which is what I had to hand and given up for today.

Any suggestions appreciated.

I have tried a threaded bar arrangement to jack the pins out but getting nowhere. One pin has budged about 2mm and the other has not moved . I tried tapping the moved pin back in with no success.

I am thinking a slide hammer will not help due to insufficient energy.

I have applied lots of WD40 which is what I had to hand and given up for today.

Any suggestions appreciated.