seadog30

Well-Known Member

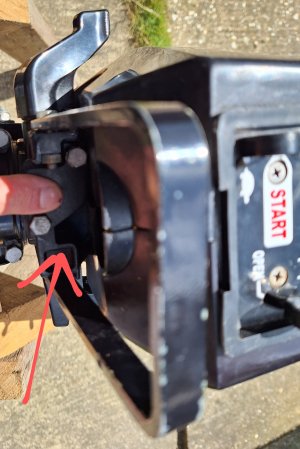

Tohatsu 2 stroke 3.5hp plastic gearlever.

The gear lever works but is so stiff that I am concerned that it could break. I have soaked the area where the shaft enters the engine case with release oil with no change.

Advice please.

The gear lever works but is so stiff that I am concerned that it could break. I have soaked the area where the shaft enters the engine case with release oil with no change.

Advice please.