Sea Change

Well-Known Member

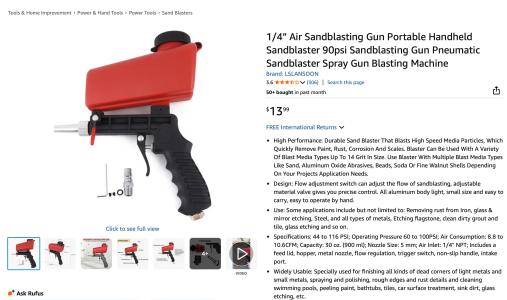

By the way, this is the sort of thing I'm talking about. It does look a bit like a toy. But after watching a few youtubers using them, it looks perfect for the little spots that I have to tackle. Will there really be all that much dust from this? I'd have thought that a good shop vac could keep up.

The boat will be tented anyway for shade.

The boat will be tented anyway for shade.