Dalestr

New Member

Well, Dinghyman, I saw the bleeders but assumed they were just bleeder screws but I now see they have the valve body as well so they are adapters.

One further advantage with vacuum bleeding is that you clearly see transition from gaseous mix to liquid in the clear suction tube. Then you just wrench close off screw valve. You do want the nipple to be vertical if feasible.

To Roger's comment above, the vacuum pump bleeder kits include a liquid collector/separator canister which can collect the bit of diesel while passing the air.

One further advantage with vacuum bleeding is that you clearly see transition from gaseous mix to liquid in the clear suction tube. Then you just wrench close off screw valve. You do want the nipple to be vertical if feasible.

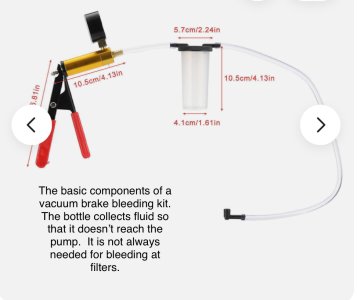

To Roger's comment above, the vacuum pump bleeder kits include a liquid collector/separator canister which can collect the bit of diesel while passing the air.