Dalestr

New Member

Inherent Yanmar Leakage

Some of the GM series Yanmars built before 1998, before they added self-bleeding to the multi-cylinder models, will ooze a bit of fuel at the secondary filter bleed screw, or at the lift pump on days with large ambient temperature swings. The lift pump allows fuel to pass through as it contracts when cooling but then blocks its retreat as it expands on a warm day. An abnormally high pressure is then reached and the weakest gasket lets a bit of fuel pass to relieve the pressure. This is an intermittent weep. Some of the fuel piping on the earlier 2GM20F, for example, is steel tubing instead of hose. Hose can expand somewhat under pressure but not steel.

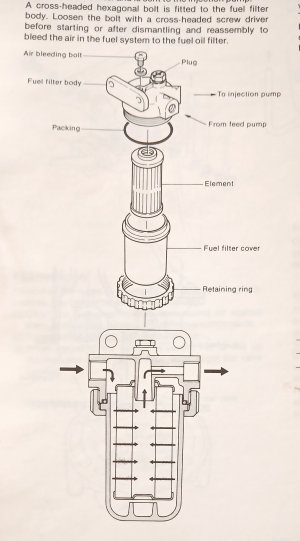

The owner detects a weep of fuel and tightens the small bleed screw on the filter more and more. This screw uses a nylon washer of a specific size, so buy these from Yanmar. There is a landing surface under that washer with an elevated ring like a donut, to help it seal (it is not a flat surface). Too much torque applied and the threads can get stripped but it is a good design in a bad situation.

How to fix the thermo-siphoning problem?

If one strips the threads of the bleeder you can plug it for life with epoxy and then use the M8 bolt for bleeding.

Some of the GM series Yanmars built before 1998, before they added self-bleeding to the multi-cylinder models, will ooze a bit of fuel at the secondary filter bleed screw, or at the lift pump on days with large ambient temperature swings. The lift pump allows fuel to pass through as it contracts when cooling but then blocks its retreat as it expands on a warm day. An abnormally high pressure is then reached and the weakest gasket lets a bit of fuel pass to relieve the pressure. This is an intermittent weep. Some of the fuel piping on the earlier 2GM20F, for example, is steel tubing instead of hose. Hose can expand somewhat under pressure but not steel.

The owner detects a weep of fuel and tightens the small bleed screw on the filter more and more. This screw uses a nylon washer of a specific size, so buy these from Yanmar. There is a landing surface under that washer with an elevated ring like a donut, to help it seal (it is not a flat surface). Too much torque applied and the threads can get stripped but it is a good design in a bad situation.

How to fix the thermo-siphoning problem?

- I’d consider replacing the steel pipe going from the lift pump to the secondary filter with a good length of hose to allow more expansion. 1/4” hose is sufficient and the less fuel volume, the less expansion there is. The fuel pump uses M8 banjo bolts but the inlet/outlet of the filter uses M12. You would need to buy banjos with hose barbs.

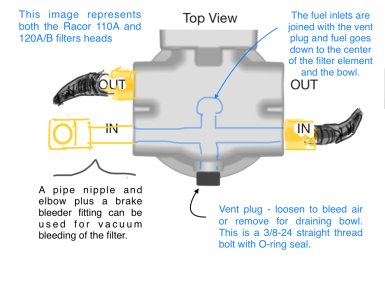

- A more sure-fire fix allows you to leave that steel piping but essentially adds an expansion tank at the unused large port on the filter top. This is designed for an M8 banjo fitting and you would run a hose from this, about 24” long, filled mainly with air, locked in a steep upward direction, with a sealed plug in the end.

- One more complex fix would be to make the fuel pump check valves imperfect by filing/grinding a very slight notch to the valve seats. A slight-passageway is enough.

If one strips the threads of the bleeder you can plug it for life with epoxy and then use the M8 bolt for bleeding.