stranded

Well-known member

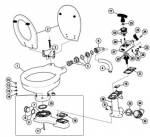

Spent best part of yesterday wrestling to replace the 38mm waste hose on our Jabsco loo. Wasn’t looking forward to it because I thought it might be a mucky job, but had no idea how bloody difficult to manipulate the cheap white sanitation hose is - arms are literally bruised from hand to shoulder - seems like I should have read here first and gone for the nice squidgy butyl type.

Anyway, after a futile couple of hours trying to get the last joint over the seacock tail without being able to address it directly because the hose was slightly offset by the toilet bowl, I removed the bowl. Those in the know will doubtless be chuckling as they will know that when I had undone the last nut and dislodged the bowl the bolts fell tink, tink, tink, tink into the jabsco base unit. Flip! So now I have lovely new shiny hose but a toilet bowl I can’t refit. I really don’t want to remove the base unit as I fear the same will happen with those bolts and I can find no way to access the underside to refit them, which to me looks like it means ripping the whole heads apart. But before I depress myself contemplating that prospect, is there a trick worth trying to retrieve the bolts from within the base unit - I can see them all sitting there- perfectly aligned, winking at me. I have thought maybe a piece of rod with superglue on the end to pull them through and slip the nut down?

Help - please!

Anyway, after a futile couple of hours trying to get the last joint over the seacock tail without being able to address it directly because the hose was slightly offset by the toilet bowl, I removed the bowl. Those in the know will doubtless be chuckling as they will know that when I had undone the last nut and dislodged the bowl the bolts fell tink, tink, tink, tink into the jabsco base unit. Flip! So now I have lovely new shiny hose but a toilet bowl I can’t refit. I really don’t want to remove the base unit as I fear the same will happen with those bolts and I can find no way to access the underside to refit them, which to me looks like it means ripping the whole heads apart. But before I depress myself contemplating that prospect, is there a trick worth trying to retrieve the bolts from within the base unit - I can see them all sitting there- perfectly aligned, winking at me. I have thought maybe a piece of rod with superglue on the end to pull them through and slip the nut down?

Help - please!

Last edited: