banflu1

Active Member

So yesterday I used Liqui moly engine flush plus on the port engine. First I let it reach 150F, turned it off, added the flush, then let it idle for 15 mins.

I drained it immediately, replaced the filter once again and refilled with the same oil (Fuchs truck plus 15w40 vds-3).

After that I went for a test run.

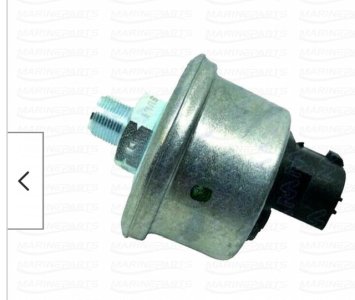

After the engine is hot (175F), the oil pressure varies from ~40 psi at idle to ~85 psi at full throttle.

It is all within spec so I’m not overly concerned, however, the other engine doesn’t go over 65/70 psi even at WOT when hot. So something must have happened to cause this change.

There is still a minor oil leak below the engine / back side, and my mechanic should try and find it’s cause next week.

I drained it immediately, replaced the filter once again and refilled with the same oil (Fuchs truck plus 15w40 vds-3).

After that I went for a test run.

After the engine is hot (175F), the oil pressure varies from ~40 psi at idle to ~85 psi at full throttle.

It is all within spec so I’m not overly concerned, however, the other engine doesn’t go over 65/70 psi even at WOT when hot. So something must have happened to cause this change.

There is still a minor oil leak below the engine / back side, and my mechanic should try and find it’s cause next week.