Star-Lord

Well-known member

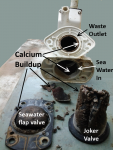

Jabsco manual - changed the whole right side pump unit because the last one started leaking. Now no leaks. Not used much.. I prefer bucket. Now I have crew... Liquids go through like a dream so thought it was all fixed. Experimented with a sit down solid the other day and it took 40mins to pump through. Obviously there is a blockage. Back to bucket. But neighbours reckon the more it is used the blockage might unblock.... I think the proof it is blocked without having to test it again with solids is the 'n' bend next to the heads under the sink... There is a valve on top of the 'n' and even when pumping water it hisses and dribbles a bit of water... If you put your finger on top of the valve it is always wet. Is this proof enough for neighbours and crew to be resigned to using the bucket? (final destination a boatyard).