Restoration man

Well-Known Member

The core of my front deck around the winch and cleats is wet on my 1975 storebro biscay 31 that I’m restoring , I plan on fixing this from inside as I don’t want to ruin the none slip on the deck ,to do it this way entails removing the front bulkhead that also is the chain locker , it’s only glassed / tabbed in on the inside, it would be easy enough to run a multi tool around the outside and cut the tabbing off flush with the hull but it’s going to be impossible for me to fit through the little door to re tab / fiberglass this back in place , this leaves me with a couple of options as I see it ,

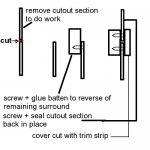

1) cut the bulkhead out leaving 4” of the original wood still attached to the tabbing and then make a new bulkhead and when time comes to refit drill some holes through both and use some carriage bolts and nuts the type that have dome head and little square on the back of the head and and put epoxy between the wood and bolt it together, see photo shopped picture

2) try run my multi tool between the tabbing and the rear face of the bulkhead separate them I might just about be able to get in enough to do that, see photo that should leave just the tabbing that is quite thick , and when time comes to go back together again use same nuts bolts as no1 and basically epoxy it back on and use the nuts and bolts as well,

Thankfully the bulkhead is only attached down the to sides and not across the top ,

Option 2 would be better as I won’t have to make a new chain locker bulkhead ,

I could also tabb it from the outside but there not really enough depth to get wide enough tab As it would be seen when side panels go back on ,but I could do this where it won’t be seen as a belt and braces approach, If I do either of the other other ways ,

The bulkheads are obviously fitted before the superstructure, I do wonder if they made the tabbing prior to fitting the bulkheads and just glued the bulkheads on as tabbing has a cut edge and is very neat , all the other bulkheads use same neatly cut tabs ,

1) cut the bulkhead out leaving 4” of the original wood still attached to the tabbing and then make a new bulkhead and when time comes to refit drill some holes through both and use some carriage bolts and nuts the type that have dome head and little square on the back of the head and and put epoxy between the wood and bolt it together, see photo shopped picture

2) try run my multi tool between the tabbing and the rear face of the bulkhead separate them I might just about be able to get in enough to do that, see photo that should leave just the tabbing that is quite thick , and when time comes to go back together again use same nuts bolts as no1 and basically epoxy it back on and use the nuts and bolts as well,

Thankfully the bulkhead is only attached down the to sides and not across the top ,

Option 2 would be better as I won’t have to make a new chain locker bulkhead ,

I could also tabb it from the outside but there not really enough depth to get wide enough tab As it would be seen when side panels go back on ,but I could do this where it won’t be seen as a belt and braces approach, If I do either of the other other ways ,

The bulkheads are obviously fitted before the superstructure, I do wonder if they made the tabbing prior to fitting the bulkheads and just glued the bulkheads on as tabbing has a cut edge and is very neat , all the other bulkheads use same neatly cut tabs ,

Attachments

-

BCA1D9AE-0546-43D6-B5FA-6C34E368F25E.jpg8.8 KB · Views: 53

BCA1D9AE-0546-43D6-B5FA-6C34E368F25E.jpg8.8 KB · Views: 53 -

C2278863-E10B-4034-B726-8F5E643FF974.jpeg9.6 KB · Views: 54

C2278863-E10B-4034-B726-8F5E643FF974.jpeg9.6 KB · Views: 54 -

13247F5F-370A-41D5-A21D-110E3145AEC4.jpg8.2 KB · Views: 47

13247F5F-370A-41D5-A21D-110E3145AEC4.jpg8.2 KB · Views: 47 -

718641EC-7C71-4F9C-8F07-FBE316EE05E6.jpg8.9 KB · Views: 44

718641EC-7C71-4F9C-8F07-FBE316EE05E6.jpg8.9 KB · Views: 44 -

46DD5D31-C3FD-4F02-9084-61BB118E9221.jpeg34.2 KB · Views: 40

46DD5D31-C3FD-4F02-9084-61BB118E9221.jpeg34.2 KB · Views: 40