halcyon

Well-Known Member

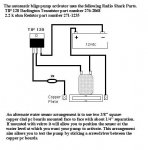

Had a quick read through, has anyone considered the old pressure switch. Pipe in bilge up to industrial pressure switch in cabin, pipe feed from upturned 'tin' to stop clogging, switch in cain in dry. Water fills up inverted 'can' creating pressure closing switch, basically no moving parts, no electronics and 'dry' location.

Brian

Brian