zoidberg

Well-known member

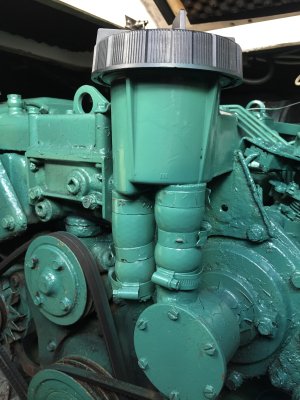

There are frequent posts, on various forums, about bits of damaged raw water impellers blocking heat exchangers, giving overheated engines.* ( see addendum #5 ) The idea of inserting a coarse mesh filter downstream from the water pump/impeller seems to have polarised opinion. It's quite common practice, I understand, on commercial craft.

Here's one example, from chandler Force 4, costing about £10...

What does the team think?

Here's one example, from chandler Force 4, costing about £10...

What does the team think?

Last edited: