skedaddle

New Member

I am hoping somebody has some experience with the CAV DPA Injection pumps on Perkins 6-354.

The story is. I have purchased outright a rebuilt pump complete. The vendor promised that it would be exactly the same configuration as the existing pump by the specs on the original pump. ie a one for one bolt in replacement.

As you will have guessed that was not the case.

There are 3 problems that I have tried to solve.

First was that the engine could not pull above 1200 rpm on the new pump. That I believe is now solved

Problem 2 is that the engine will stall when engaging Fwd or Reverse. This occurs with the pump/engine set to exactly the same idle speed as was the original pump. It does not just abruptly stall, it just slowly fades away down to a stop. If however if you engage Fwd or Rev and "blip" the throttle it will not fade out and stall. It will hold idle at 200 - 300 rpms down from set idle.

Problem 3 With the previous pump the engine would start at the turn of the key. No throttle required and hestation what so ever. With the new pump you must apply throttle to get the engine started. This combined with 2 is a major issue on a boat with a single lever control.

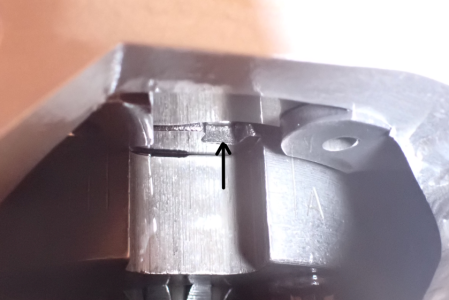

My guess is that 2 & 3 are a Govenor related issue. I have checked the Governor spring positions and free lengths between both pumps and they are the same. There is a excellent very old movie on made by Perlins/CAV about the pump on You Tube. After watching that I still cannot see what it is that I need to adjust to make the Pump Governor more sensitive at low speed.

Thank you

The story is. I have purchased outright a rebuilt pump complete. The vendor promised that it would be exactly the same configuration as the existing pump by the specs on the original pump. ie a one for one bolt in replacement.

As you will have guessed that was not the case.

There are 3 problems that I have tried to solve.

First was that the engine could not pull above 1200 rpm on the new pump. That I believe is now solved

Problem 2 is that the engine will stall when engaging Fwd or Reverse. This occurs with the pump/engine set to exactly the same idle speed as was the original pump. It does not just abruptly stall, it just slowly fades away down to a stop. If however if you engage Fwd or Rev and "blip" the throttle it will not fade out and stall. It will hold idle at 200 - 300 rpms down from set idle.

Problem 3 With the previous pump the engine would start at the turn of the key. No throttle required and hestation what so ever. With the new pump you must apply throttle to get the engine started. This combined with 2 is a major issue on a boat with a single lever control.

My guess is that 2 & 3 are a Govenor related issue. I have checked the Governor spring positions and free lengths between both pumps and they are the same. There is a excellent very old movie on made by Perlins/CAV about the pump on You Tube. After watching that I still cannot see what it is that I need to adjust to make the Pump Governor more sensitive at low speed.

Thank you