DesertIsland

New member

Firstly sorry for the long post. I am attempting to provide all the required information for my situation to make sense to someone who has the patience to read it all!

I am planning to replace the factory fitted bridle on my Fountaine Pagot Astrea 42. She is 12.58m LOA (just under 42ft) 7.2m beam (just over 23.5ft) and just shy of 15000kg fully laden.

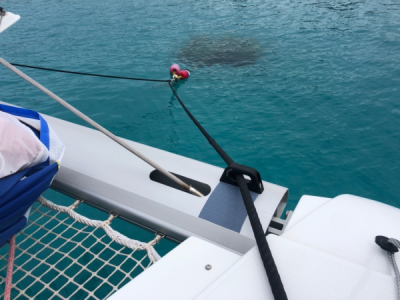

Currently each leg is approx 5m long, fixed to each bow through the cross beam brackets with a bowline and having a shamefully inadequate snap shackle where the two legs join as the connector to the chain. To be fair, it works, however it is, to my mind, completely inadequate for anchoring in anything other than benign conditions. I would provide a photo however I am not on the boat until a week today.

My first instinct was to replace it with a longer bridle than currently installed and go 20mm Dia nylon anchor plait or similar and a proper anchor hook. However I came across an article in Practical Sailor which has caused me to pause, reconsider and seek further information/ advice.

I therefore searched and read all the posts I could find on the subject here on YBW, many either highlighted as good info or were written by Jonathan Neeves. Whilst I have learn’t a great deal, as yet, I do not feel I have a clear enough plan to move forward with purchasing and install. Therefore I am reaching out to the vast knowledge here and would value feedback on my current thinking and suggestions of improvement.

My current plan is to:

) however I have been unable to make enough sense of the formulas I have found relating to snatch loads and diameter of bridle rope to get meaningful results with which to make an informed decision on sizing for my situation.

) however I have been unable to make enough sense of the formulas I have found relating to snatch loads and diameter of bridle rope to get meaningful results with which to make an informed decision on sizing for my situation.

I really quite like the idea of the bridle plate designed by Jonathan Neeves and being able to run the bridle lines back to the aft cleats however I think it is not practical for me to install fixings low down on each bow. Therefore the rope would come from and go back to the ends of the cross beam creating a near 180deg turn in the rope where it passes through the bridle plate. This (rightly or wrongly) I feel would not be good for the rope and would weaken it. Although I am certainly open to be convinced.

I am planning to replace the factory fitted bridle on my Fountaine Pagot Astrea 42. She is 12.58m LOA (just under 42ft) 7.2m beam (just over 23.5ft) and just shy of 15000kg fully laden.

Currently each leg is approx 5m long, fixed to each bow through the cross beam brackets with a bowline and having a shamefully inadequate snap shackle where the two legs join as the connector to the chain. To be fair, it works, however it is, to my mind, completely inadequate for anchoring in anything other than benign conditions. I would provide a photo however I am not on the boat until a week today.

My first instinct was to replace it with a longer bridle than currently installed and go 20mm Dia nylon anchor plait or similar and a proper anchor hook. However I came across an article in Practical Sailor which has caused me to pause, reconsider and seek further information/ advice.

I therefore searched and read all the posts I could find on the subject here on YBW, many either highlighted as good info or were written by Jonathan Neeves. Whilst I have learn’t a great deal, as yet, I do not feel I have a clear enough plan to move forward with purchasing and install. Therefore I am reaching out to the vast knowledge here and would value feedback on my current thinking and suggestions of improvement.

My current plan is to:

- Fit an eye bolt fixing for each leg of the bridle such as the one from Wichard or a commercial lifting rated one like this. I am thinking M12. My concern with the commercial lifting one is if it will stand up to the high corrosion environment it will be in.

- The rope I am currently planning to use is 12 or 14mm ‘Liros Handy Elastic’ as it has a quoted working stretch of > 20% (i’m thinking good for absorbing the snatch loads).

- Each end of the bridle will have a eye splice with a stainless steel thimble and a shackle to connect it to the eye bolt.

- Each bridle leg will have a Unimer U-Cleat mooring compensator.

- The finished length of each leg (with the U-Cleats in place) is planned to be 7m.

- The middle of the bridle will have a stainless steel thimble eye spliced into it.

- Use a chain hook shackled to the thimble to connect to the chain. The chain we have is 100m of G70 8mm galvanised chain.

I really quite like the idea of the bridle plate designed by Jonathan Neeves and being able to run the bridle lines back to the aft cleats however I think it is not practical for me to install fixings low down on each bow. Therefore the rope would come from and go back to the ends of the cross beam creating a near 180deg turn in the rope where it passes through the bridle plate. This (rightly or wrongly) I feel would not be good for the rope and would weaken it. Although I am certainly open to be convinced.