stacer

New Member

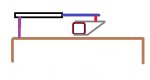

I have recently bought a boat with a canoe stern which will pose difficulties in fitting my ageing Autohelm 1000. Most solutions seem to involve the use of a bracket to position the unit outboard and obtain the required distance to the tiller. I have seen a post on here from a member “Behome” which indicated that the unit was positioned inboard and the tiller pin on a bracket which positioned it to the port side of the tiller. I would be very interested in seeing this system as in a very small boat like mine, space is at a premium and I am anxious to avoid unnecessary outboard fittings. Any help or information would be much appreciated.