wonkywinch

Well-known member

Checking the oil level in the sail drive, when opening the cap, excess oil with a small amount of "mayonnaise" flowed out. I only recently replaced the oil during lift out in May and it has been at the correct level.

During the time on the hard, I fitted a Darglow rope cutter and the running has been smooth until a few days ago there was noticeable vibration at 2200 rpm when motoring. This cleared after running astern and a quick blast of power.

I don't check the sail drive oil every day so probably 25 hours on the engine since last check when all was well.

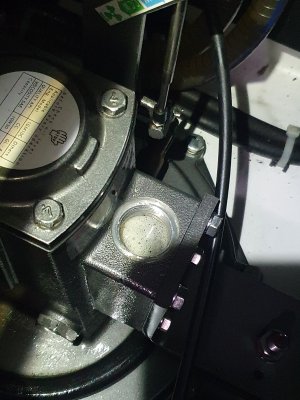

I mopped out oil surplus and checking again after 24 hours, it looks like this (image below). No increase in level whilst sitting on pontoon without running the engine.

I guess the 2016 boat has the original seal and there is evidence of a very little black oil coming out from the side of the seal inside engine compartment. Engine has 530 hours, 250 of those in last 14 months (our ownership).

How does water get into the oil? I might suspect prop shaft seal after adding weight of rope cutter which also extended out the prop by 3cm using the supplied extension shaft.

Does a failing main seal allow water in/oil out? The drawings look like the underwater leg is bolted directly to the gearbox in the engine compartment.

Am I safe to run the engine/prop or is this a serious no go?

Based Hamble but currently in the Yealm, next stop Dartmouth where engineering help can be sought but if the boat is going to be out of the water, I prefer a return to base. Can sail but not much wind forecast this week.

Photo taken 24 hours after emulsion cleaned away.

During the time on the hard, I fitted a Darglow rope cutter and the running has been smooth until a few days ago there was noticeable vibration at 2200 rpm when motoring. This cleared after running astern and a quick blast of power.

I don't check the sail drive oil every day so probably 25 hours on the engine since last check when all was well.

I mopped out oil surplus and checking again after 24 hours, it looks like this (image below). No increase in level whilst sitting on pontoon without running the engine.

I guess the 2016 boat has the original seal and there is evidence of a very little black oil coming out from the side of the seal inside engine compartment. Engine has 530 hours, 250 of those in last 14 months (our ownership).

How does water get into the oil? I might suspect prop shaft seal after adding weight of rope cutter which also extended out the prop by 3cm using the supplied extension shaft.

Does a failing main seal allow water in/oil out? The drawings look like the underwater leg is bolted directly to the gearbox in the engine compartment.

Am I safe to run the engine/prop or is this a serious no go?

Based Hamble but currently in the Yealm, next stop Dartmouth where engineering help can be sought but if the boat is going to be out of the water, I prefer a return to base. Can sail but not much wind forecast this week.

Photo taken 24 hours after emulsion cleaned away.