Sailfree

Well-known member

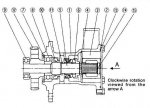

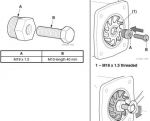

Manual says pump turns anticlockwise but install impellor by turning clockwise.

Surely this means blades are facing forwards while I would expect them to effectively be trailing!

What do I not understand or am I being stupid!!

Surely this means blades are facing forwards while I would expect them to effectively be trailing!

What do I not understand or am I being stupid!!