scw

New member

Hi there,

I am looking for some advice on an issue that has just started to happen with my Volvo Penta MD7A / 110S Sail Drive.

I’ve been regularly starting and running the engine over the winter and getting the boat ready for the summer season, and a few weeks ago I noticed a clunking sound that was coming up from, I think, the sail drive leg.

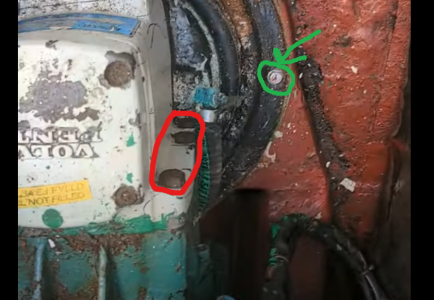

The clunking appears to only happen in forward gear; I have not yet been able to replicate it in reverse. The last time I ran it, I had it in forward gear for about 4 minutes before the clunking started happening, whereas previously it'd happened within a minute of being in gear. I thought maybe the prop or roper cutter had come loose, or maybe something was wrapped around the prop. In order to rule a few things out, I went under the boat to look (she sits in mud at low tide). Other than it looking dirty and needing a coat of paint and maybe a new anode, everything looks ok, or so I believe. I’m no expert with boats or engines, so please correct me if you see anything alarming in the attached photos or videos. When in gear, the boat does move forward, so the prop is turning okay, although it might be losing a bit of power. It's hard to tell as it’s only a 13-HP engine and tidal, so getting a true gauge is difficult. The sail drive oil is at the correct level and looks very clean. Engine oil is also at the right level and looks ok.

Here are the videos that show the engine running and the prop movement.

-

I am at a bit of a loss for how to find the cause so that I can fix the issue. If she needs to come out of the water, I would ideally like to know what I am looking to fix or order beforehand. Any help would be much appreciated.

Many thanks for looking.

I am looking for some advice on an issue that has just started to happen with my Volvo Penta MD7A / 110S Sail Drive.

I’ve been regularly starting and running the engine over the winter and getting the boat ready for the summer season, and a few weeks ago I noticed a clunking sound that was coming up from, I think, the sail drive leg.

The clunking appears to only happen in forward gear; I have not yet been able to replicate it in reverse. The last time I ran it, I had it in forward gear for about 4 minutes before the clunking started happening, whereas previously it'd happened within a minute of being in gear. I thought maybe the prop or roper cutter had come loose, or maybe something was wrapped around the prop. In order to rule a few things out, I went under the boat to look (she sits in mud at low tide). Other than it looking dirty and needing a coat of paint and maybe a new anode, everything looks ok, or so I believe. I’m no expert with boats or engines, so please correct me if you see anything alarming in the attached photos or videos. When in gear, the boat does move forward, so the prop is turning okay, although it might be losing a bit of power. It's hard to tell as it’s only a 13-HP engine and tidal, so getting a true gauge is difficult. The sail drive oil is at the correct level and looks very clean. Engine oil is also at the right level and looks ok.

Here are the videos that show the engine running and the prop movement.

I am at a bit of a loss for how to find the cause so that I can fix the issue. If she needs to come out of the water, I would ideally like to know what I am looking to fix or order beforehand. Any help would be much appreciated.

Many thanks for looking.