Samwise2111

New Member

If there is nothing burnt on the PCB, but it still does not work and shows no reaction to the push of any button, we would be interested in getting our hands on one. Or any that have these symptoms, so that we can continue the research. The box might be repaired in the process (no promises, as it depends on the cause of the failure).As for symptoms.. There were none... Just instantaneous failure.

My MDI had two issues:

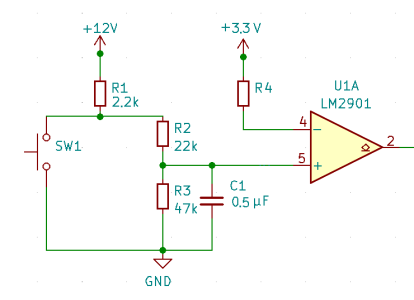

1. An MLCC was broken and had become slightly conductive. As a result, a button was permanently recognised as pressed, which sent the LPC into the bootloader. Then it is still up and running, but it will not react to any buttons nor switch power to the panel etc.

2. The LPC should go into power-down mode when not in use. It did not. It got stuck in the process. This is a strange error. It may indicate a defect in the LPC. But after desoldering, the LPC worked just fine, as does a new one soldered onto the PCB.

So we cannot investigate the cause - because my MDI is now repaired..