Refueler

Well-Known Member

Setting up my Primor 24 for the River Festival .. I find that 'gardener' has left electric supply cable unplugged .... batterys on board are 'end of life' but with only river use - have been fine ... till today !

Batterys are dead !! Tried Booster .. tried quick charge .. in the end of to shop and pair of replacement batterys ...

Engine starts but sounds strange and smoke ! Smoke clears and all seems ok ... engine sound is a bit louder - but we put that down to having engine bay open to change batterys. Close up bay ... engine runs for a bit then stops .. starter spins her over but she won't keep running ... in the end we understand there is a hole in manifold collector ... exhaust gas is filling bay and engine starved of oxygen.

The River Fest is something we've really been looking fwd to .. so we decide to run with engine bay open ... bit noisy - but at least she's running.

We arrive at meeting point - by now engine is more noisy - obviously the hole is getting bigger !! We are a little early - so we nose her up the bank ... this raises bow - puts stern lower ... we see water coming in .. obviously the hole is now below water level ... pump is managing fine ..

We pull back of the bank - water stops ... but now engine is loud !

Decision ... go home or stay with the Festival ? We decide that because most are row boats / kayaks ... we can get by on tick-over and not too loud ..

Great day had ... but back to three troubles :

1. Exhaust / water collector on manifold has big hole !! Volvo Penta AQ170 (its the Volvo 364 3litre engine)

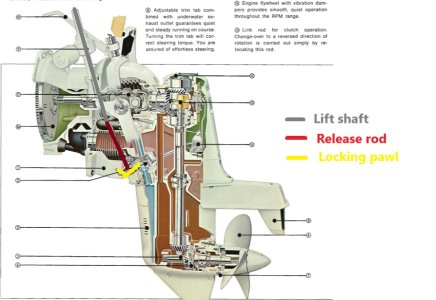

2. Outdrive lift failed - only click - click when button pressed .. we tried with rope over stern but outdrive is 'locked' down.

3. After festival - we put boat on her trailer (she's to go to yard for new canopy anyway) - we find the locking mechanism for going astern (stops prop kicking up) is stuck and connection to gear shift is broken. This explains #2 and why now #2 does not work at all - obviously strained the lift motor.

Looks like I am going to have a hefty bill at the yard !!

Batterys are dead !! Tried Booster .. tried quick charge .. in the end of to shop and pair of replacement batterys ...

Engine starts but sounds strange and smoke ! Smoke clears and all seems ok ... engine sound is a bit louder - but we put that down to having engine bay open to change batterys. Close up bay ... engine runs for a bit then stops .. starter spins her over but she won't keep running ... in the end we understand there is a hole in manifold collector ... exhaust gas is filling bay and engine starved of oxygen.

The River Fest is something we've really been looking fwd to .. so we decide to run with engine bay open ... bit noisy - but at least she's running.

We arrive at meeting point - by now engine is more noisy - obviously the hole is getting bigger !! We are a little early - so we nose her up the bank ... this raises bow - puts stern lower ... we see water coming in .. obviously the hole is now below water level ... pump is managing fine ..

We pull back of the bank - water stops ... but now engine is loud !

Decision ... go home or stay with the Festival ? We decide that because most are row boats / kayaks ... we can get by on tick-over and not too loud ..

Great day had ... but back to three troubles :

1. Exhaust / water collector on manifold has big hole !! Volvo Penta AQ170 (its the Volvo 364 3litre engine)

2. Outdrive lift failed - only click - click when button pressed .. we tried with rope over stern but outdrive is 'locked' down.

3. After festival - we put boat on her trailer (she's to go to yard for new canopy anyway) - we find the locking mechanism for going astern (stops prop kicking up) is stuck and connection to gear shift is broken. This explains #2 and why now #2 does not work at all - obviously strained the lift motor.

Looks like I am going to have a hefty bill at the yard !!