dgadee

Well-Known Member

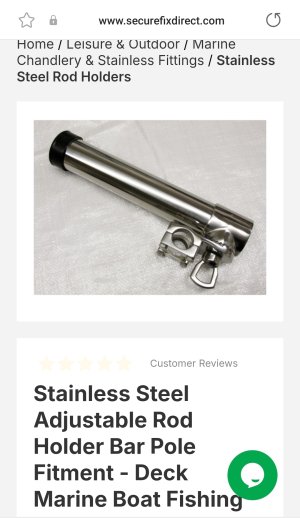

Anyone seen one of these in UK?

Seen it at autocazantes.com – Conversión de winches, restauraciones, accesorios but they seem to sell whole solar kits.

Seen it at autocazantes.com – Conversión de winches, restauraciones, accesorios but they seem to sell whole solar kits.