Lomax

Well-Known Member

With the abysmal weather preventing any outside work, I've turned my attention to the design of the fridge/freezer. I've long had the idea of using some kind of plastic bins as the compartments, not only to save time, but because they would provide a smooth, easy-clean and durable interior. After some searching I think I've found a good option in Wham's "recycling bins" (minus lids):

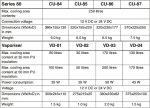

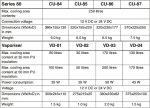

I have a Waeco/Dometic CU-85 compressor with the "L" shaped VD-01 evaporator plate:

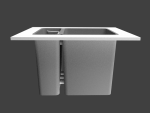

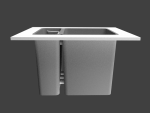

The idea is to use the smaller 25L bin as a "freezer" compartment, with the evaporator mounted on the wall separating it from the "fridge" compartment. The two compartments are connected along the top and bottom by six 50mm diameter pipes, which can be selectively plugged to control the airflow. The top three holes (allowing "warm" air to move from the "fridge" to the "freezer") are behind the top of the evaporator plate, but as this is mounted on 16mm stand-offs there's still room for the air to move. The bottom three holes are below the evaporator and unrestricted. This combined unit would then be routered into the "lid" of a plywood box sized to allow 10-15cm of insulation all around. The insulation would be a two-part PU foam, introduced through a series of holes in the box's "lid" and allowed to completely fill the box, after which the actual worktop itself is mounted on top (with hinged lids for the fridge/freezer compartments - not shown below). Some illustrations:

What do you guys think, is this a viable design? Do you see any obvious problems?

I have a Waeco/Dometic CU-85 compressor with the "L" shaped VD-01 evaporator plate:

The idea is to use the smaller 25L bin as a "freezer" compartment, with the evaporator mounted on the wall separating it from the "fridge" compartment. The two compartments are connected along the top and bottom by six 50mm diameter pipes, which can be selectively plugged to control the airflow. The top three holes (allowing "warm" air to move from the "fridge" to the "freezer") are behind the top of the evaporator plate, but as this is mounted on 16mm stand-offs there's still room for the air to move. The bottom three holes are below the evaporator and unrestricted. This combined unit would then be routered into the "lid" of a plywood box sized to allow 10-15cm of insulation all around. The insulation would be a two-part PU foam, introduced through a series of holes in the box's "lid" and allowed to completely fill the box, after which the actual worktop itself is mounted on top (with hinged lids for the fridge/freezer compartments - not shown below). Some illustrations:

What do you guys think, is this a viable design? Do you see any obvious problems?

Last edited: