dsw

Well-Known Member

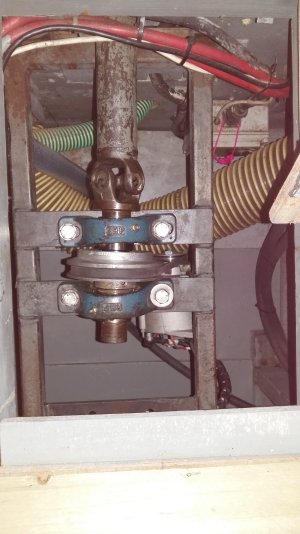

Any thoughts of this setup which charges the 12v bank.

Shaft bolted to the crank shaft pulley (350hp sabre) which

Has 2 U Joints into 2 Plummer bearings which i have noticed

Are fixed to the shaft so it can’t move forward or back even after

I removed the grub screws.

Reason i ask is vibration at certain speeds and i hate vibrations.

Plus not really enough room to fit an alternator to the engine.

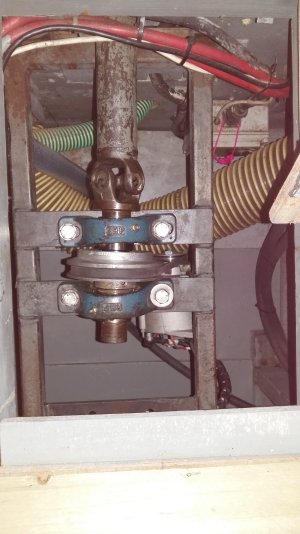

Shaft bolted to the crank shaft pulley (350hp sabre) which

Has 2 U Joints into 2 Plummer bearings which i have noticed

Are fixed to the shaft so it can’t move forward or back even after

I removed the grub screws.

Reason i ask is vibration at certain speeds and i hate vibrations.

Plus not really enough room to fit an alternator to the engine.