bedouin

Well-Known Member

My boat has an internal GRP moulding maybe 3mm thick. In several places it has access panels etc screwed on using self tapping screws. Over the years with regular use the screws get looser and looser - so you go to the next size up and that only makes things worse.

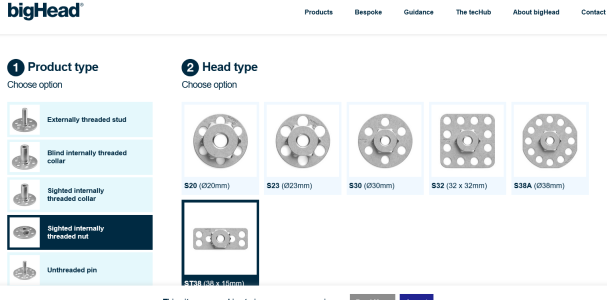

I am sure there must be a better solution - has anyone tried rivnuts or jack nuts or similar solution?

I am sure there must be a better solution - has anyone tried rivnuts or jack nuts or similar solution?