thinwater

Well-Known Member

The other thing is that compared to a monohull with a deep spade rudder, a short cat skeg hung rudder has very little bending force on the shaft. You don't need the stiffness of carbon. Totally different beast.

Carbon rudders have a reputation for snapping suddenly. It may be less of an issue on a skeg supported rudder. The only failures I have seen were carbon spade rudders. It was interesting to see the construction of the failed rudder stock on a friends race boat. It was carbon rods wrapped in a bundle to form a larger diameter carbon shaft. Apparently this is the best possible and strongest way to build a carbon shaft. Even so, it still failed.The problem with stainless is it can corrode and embedded in a foam core seems exactly the sort of place - if it went wrong - that oxygen depleted water would cause corrosion which simply can’t happen with composites

It’s the same reason my bronze through hull will be replaced with TruDesign and my stainless chainplates are being replaced with carbon I’m laminating in to the hull etc I’m just building a new toe rail to replace the aluminium one that having lasted 40 years is corroding so I’ll laminate in a grp one (which also seals all those pesky screw holes for the toe rail in to deck) and laminate in grp stanchions at the same time … if I can make it not corrode or rust or need maintenance I just think I might as well

I bent a shaft once on a log floating below the surface. Only a few degrees, but enough that it rubbed on the hull. I bent it back, which was a careful process, but took only a few hours and some careful application of force. With carbon it would have snapped and floated away. Much worse.

For me this is not a hypothetical.

I didn't even remove it from the boat. I built a V-shaped saddle to closely fit and support the trailing edge, so as not to damamge the foam and structure, calculated the required force and the amount of over-bend required to allow for spring-back, and gave it a slow pull (chain fall pulled by a winch, monitored with a strain gauge). Got it the first time. As it turns out, the force is not nearly enough to tax the bearings if carefully applied.Straighten stainless steel shafts is easy with a garage press and some roller Vee blocks.

If you need accuracy a dial gauge will help.

Used to straighten shafts during my Engineering apprenticeship but today we throw it away and pay good money for a new one

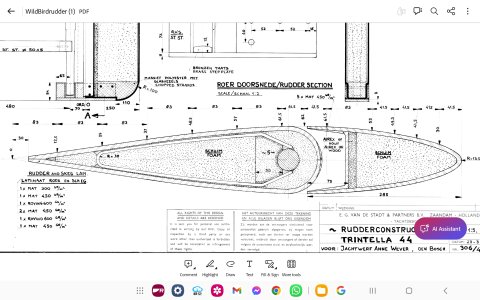

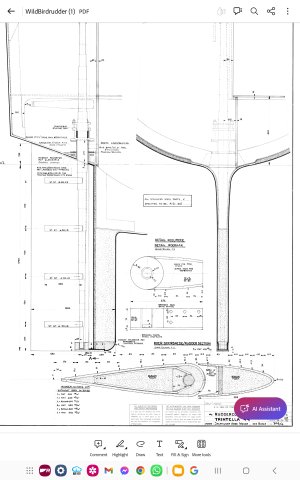

It is easy to stop water getting in with a cored and sheathed rudder as there are no joins unlike a moulded rudder, just the stock entry. On the rudder I made that was sealed with epoxy and was sound 25 years later when I sold the boat. Jefa use an O ring at this point on their rudders. Photo of your existing rudders would be useful and also how they are mounted on the skegs.

You should not need anodes on a stainless rudder and stock if it is only the stainless that is in the water.

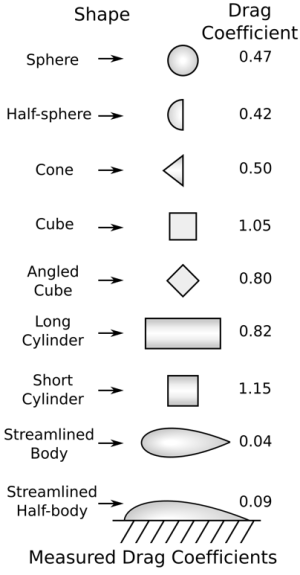

The rudders only form a small part of the vessel’s total drag, but it is amazing how much reduction in drag occurs with a streamlined shape. It is a much greater difference than you may intuitively think.I assume that it will also reduce drag slightly so I can go faster ... whether any known log could measure the incremental increase is another matter

Welded a washer on the shaft top of the blade to form a pocket which then got filled with epoxy when I sheathed it. Jefa suggest filling the pocket on their rudders with Sikaflex. Some Bavaria owners have done what you suggest epoxy an O ring into a pocket. At the bottom a similar washer was left flush as a bearing surface for the bottom bearing which was a top hat Delrin insert in the bronze shoe. The blade construction was ply attached to the usual tangs and framed in solid wood then sheathed in epoxy glass cloth. Not a good profile as I had been seduced by a convincing argument from an owner of a sister ship that flat with a concave trailing edge was nearly as good as a foil. It was a vast improvement over the flat plate but was never convinced that the concave trailing edge did anything!Just wanted to come back to this if I may - how did you ensure a perfect seal on to a stainless stock ? I have seen lots of rudders with ingress from the stock - its one of my main concerns hence wanting to use a composite stock that gives a proper bond from stock to rudder. So I would be interested to hear how your seal was made please

I'm just weighing up the idea of blasting the original steel rudders clean , bonding foam over them and shaping to profile and then encapsulating in epoxy glass fibre and fairing with epoxy. As I said water ingress from the shaft is my prime worry but if that can be designed out ( a countersunk pocket top and bottom on the shaft with an o ring covered with thickened epoxy to fill or a "top hat" with seal inside glassed in top and bottom ) then the better shape combined with the stainless rudder underneath to still work if the GRP is bitten or damaged some other way does have an appeal for an ocean cruising boat

Thanks for that - something to look in to for me between now and spring when the haul out is bookedWelded a washer on the shaft top of the blade to form a pocket which then got filled with epoxy when I sheathed it. Jefa suggest filling the pocket on their rudders with Sikaflex. Some Bavaria owners have done what you suggest epoxy an O ring into a pocket. At the bottom a similar washer was left flush as a bearing surface for the bottom bearing which was a top hat Delrin insert in the bronze shoe. The blade construction was ply attached to the usual tangs and framed in solid wood then sheathed in epoxy glass cloth. Not a good profile as I had been seduced by a convincing argument from an owner of a sister ship that flat with a concave trailing edge was nearly as good as a foil. It was a vast improvement over the flat plate but was never convinced that the concave trailing edge did anything!

The usual source of water ingress in production rudders is failure of the bonding of the two clam shell mouldings and your design will eliminate that. Your proposal is more or less how I would do it if the existing plates and stock are sound. I assume the stock has 3 bearings - bottom of skeg, entry to hull and top so the stock does not have to be anything fancy. Mine was 1" 316 for a rudder similar size and proportions to yours except it had about 10% balance area - no skeg, traditional long keel and prop aperture.