zoidberg

Well-Known Member

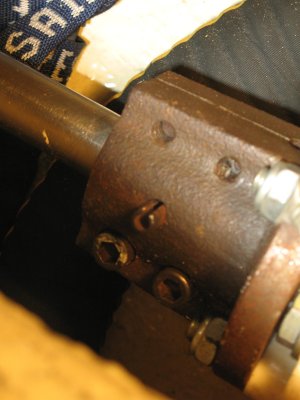

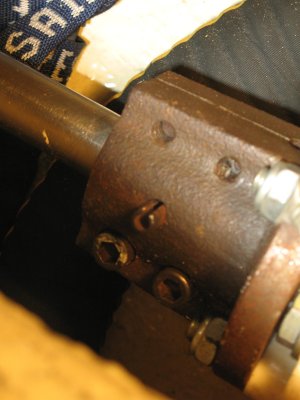

I need some informed guidance on selection and use of 'roll pins/coiled spring pins' used to hold a prop shaft to the gearbox.

When I swopped 'old-for-new' engine, I removed an old pin, then later replaced with another new one. That didn't go as well as I'd hoped.... for I knew nothing of how that ought to be done.

The replacement pin protrudes by almost half an inch. It clearly hasn't seated adequately/fully through the prop shaft and now I need to do the job properly - starting with removal.

'Tight-as-possible' mole grips have failed to budge it. I'll need to tap it out, and access is severely restricted.

I've recently learned that the hole through the prop shaft ought to be 'off-centre'....

I haven't found anything directly relevant on Youtube. Any input on A: removal, and B: replacement with a right-sized pin.... will be most welcome.

When I swopped 'old-for-new' engine, I removed an old pin, then later replaced with another new one. That didn't go as well as I'd hoped.... for I knew nothing of how that ought to be done.

The replacement pin protrudes by almost half an inch. It clearly hasn't seated adequately/fully through the prop shaft and now I need to do the job properly - starting with removal.

'Tight-as-possible' mole grips have failed to budge it. I'll need to tap it out, and access is severely restricted.

I've recently learned that the hole through the prop shaft ought to be 'off-centre'....

I haven't found anything directly relevant on Youtube. Any input on A: removal, and B: replacement with a right-sized pin.... will be most welcome.