BobnLesley

Well-Known Member

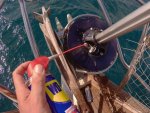

Re long circlippliers: can anyone please give necessary dimensions or a link? S

We have a set of circlip pliers much like these BERGEN 4 PC 7" Circlip Pliers Internal External Bent Nose Straight Tip Snap Ring | eBay

which have done this and many other jobs fine