simonfraser

Well-known member

Hi

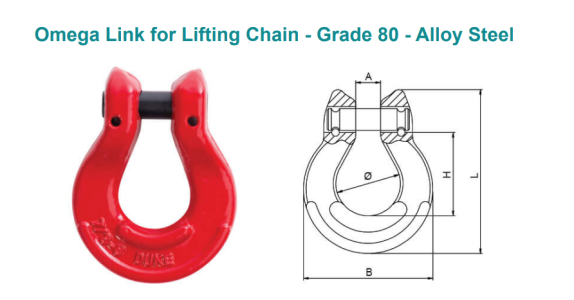

provided it all fits, i can use the black pin through the chain ?

and the red U through the anchor shaft to allow for sideways rotation ?

the small black pins 'just' push in, and locktite those, is that secure enough for anchoring ?

i'd rather not use a crosby lifting shackle as anything protruding is likely to catch on my bow gear at the worst possible moment

Tnx