rolandka

Member

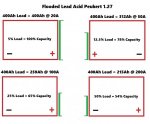

Yes, the theoretical cycle life is much greater than most lead-acid batteries. However 80% of 260Ah only gives you a usable 208Ah. If you had 400-450Ah of decent lead-acid batteries, you'd have the same usable capacity at 50% DOD, at about a third of the cost. OK, the weight would be about twice as much, but not massively more.

Yep, that is right. However, I can only use that capacity if the discharge rate is not high. If it's high then that remaining 200Ah (50% DOD) can be halfed. A 400Ah bank can supply a 20A load for 20 hours before hitting 10.5V (0% DOD). Loads above the 20 hour rating diminish the capacity of the bank.

Yes, weight is a big player here too, in case if needed I can still add a secondary lipo battery bank to the system. I don't think I would be able to do this with Lead Acid as that would weight around 250kg (550pounds). That is really a lot to carry around in van.