ianat182

Well-Known Member

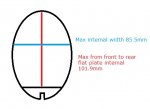

I live not too far from the Barge Chandlery and could view any mast foot they might have, but of course would need some idea of the make of the mast, or at least the dimensions of the casting required to fit INSIDE the existing mast form ,and the length from the front to the centre of the pivot, in fact any that might be critical. Are you able to re-send the original photo of the mast step itself , fully dimensioned so I can copy here. I'll get the price from them and inform you so you can deal with them and be aware of any VAT/import problems/costs.and delivery details they would need.

By the way, that Pivot hole needs trueing and some tubing insert as a 'bearing', - even using the Dural plates repair method.

ianat182

By the way, that Pivot hole needs trueing and some tubing insert as a 'bearing', - even using the Dural plates repair method.

ianat182