lustyd

Well-Known Member

This fuse isn’t for the circuit, you should also have one for that, maybe a mega/midi fuse in a distribution box. This is purely to protect against battery shorts.need 40A only

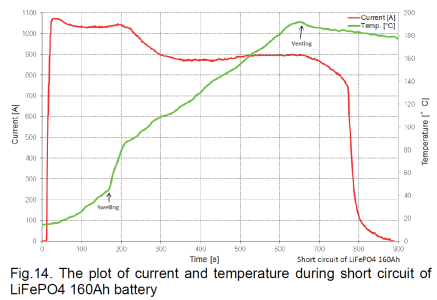

There are shorts and there are shorts. Usually a BMS can disconnect in a small event but anything big and it’ll weld closed so is not sufficient for real protection.JM states that his BMS has built Short Circuit protection