PaulRainbow

Well-Known Member

I wouldn’t assume that anything on this boat is there for a reason! Some of the original gear, assumed sound by the PO, could’ve sunk her if launched ‘as is’. It’s a mess of previous bodges…

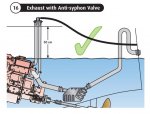

But are we saying there’s a risk of reducing (not entirely removing) the vertical ‘loop’ section? Remember that there’s an effective ‘siphon break’ vent to atmosphere, via a 10mm ID ‘piddle tube’ to a purpose made s/s breather ‘manifold’ that vents on the topside. It is easy to check visually and can’t see how it would fail without soon being noticed. And if it did block, surely a loop wouldn’t help anyway?

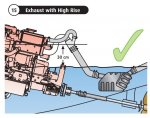

Bear in mind also have a high rise exhaust mixer with sufficient fall to the waterlock. The system is designed and specified not to hydro lock!

The waterlock is there to stop the water in the exhaust getting into the exhaust manifold, thence the engine. The vented loop or piddle pipe is there to stop the sea water that was being pumped through the cooling system from siphoning into the system and possibly entering the engine. Both devices break the siphon, when correctly installed and working.

Not much to go wrong with the piddle tube, provided it's correctly installed and doesn't get blocked (hard to see how it could get blocked, if it did, you'd likelt notice the lack of peeing). The valves in the vented loops need maintenance and checking from time to time. If the valve fails in the closed position it won't break the siphon and the engine could get water in a cylinder/s, resulting in damage.