Tim Good

Well-Known Member

Hello. We’re in Senegal and relying on our genset for our watermaker.

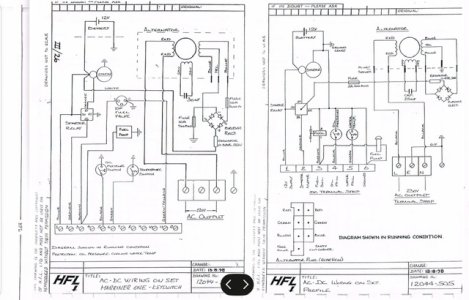

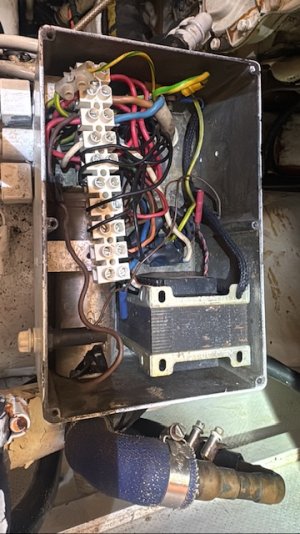

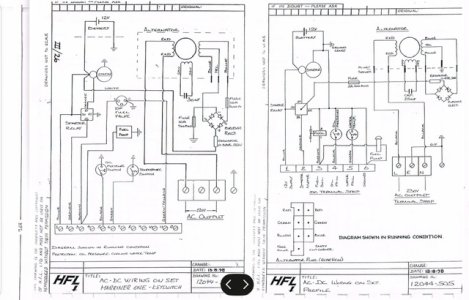

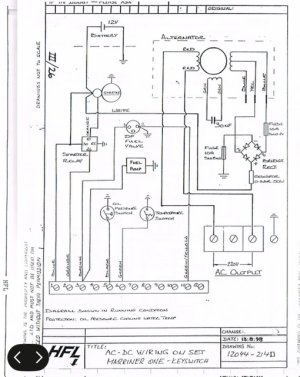

Model: HFL H2W6FIC / phase 1 / 3000RPM

It stopped outputting AC so I checked the voltage output at the genset and it’s only 8.5v. All other connections appear ok. Chat gpt suggests this could be an AVR issue but I believe my model doesn’t have an AVR.

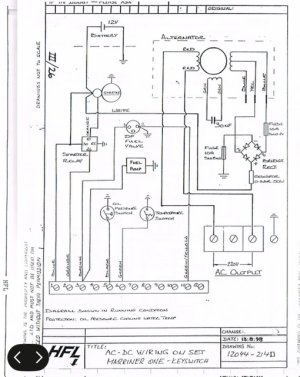

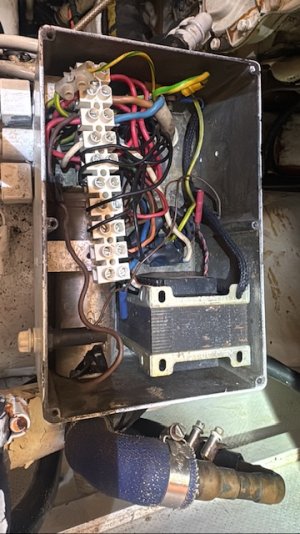

All the AC wiring comes from a large cylinder on the side of the genset; circled in red in the photo.

This is as much as I know. Can anyone suggest where I go next? It seems very difficult to access that cylinder without having the entire unit lift out.

Model: HFL H2W6FIC / phase 1 / 3000RPM

It stopped outputting AC so I checked the voltage output at the genset and it’s only 8.5v. All other connections appear ok. Chat gpt suggests this could be an AVR issue but I believe my model doesn’t have an AVR.

All the AC wiring comes from a large cylinder on the side of the genset; circled in red in the photo.

This is as much as I know. Can anyone suggest where I go next? It seems very difficult to access that cylinder without having the entire unit lift out.

Last edited: