You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrics

- Thread starter pmagowan

- Start date

lw395

Well-Known Member

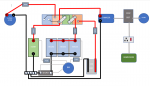

You need to tell us what the ABCD terminals on the VSR are, but it looks wrong.

The VSR is normally used to connect the two batteries together when either the alternator or the charger raise one or other to charging voltage.

If you want the shunt to tell the battery monitor how much charge the alternator is putting in, it needs to be in that circuit.

No smart charging fom the alternator?

No solar?

No fuses?

The VSR is normally used to connect the two batteries together when either the alternator or the charger raise one or other to charging voltage.

If you want the shunt to tell the battery monitor how much charge the alternator is putting in, it needs to be in that circuit.

No smart charging fom the alternator?

No solar?

No fuses?

pmagowan

Well-Known Member

The squares at the top represent a BEP cluster of Start/House/Parallel and VSR.

I think I need to move the shunt. The installation instructions talk about 'main' battery and 'auxillary' battery. I took that to mean main=start aux=house but I suspect I have that back to front

I think I need to move the shunt. The installation instructions talk about 'main' battery and 'auxillary' battery. I took that to mean main=start aux=house but I suspect I have that back to front

Last edited:

neil1967

Well-Known Member

You don't appear to have any way of charging the start battery - no connection to the +ve of the start battery

pmagowan

Well-Known Member

You don't appear to have any way of charging the start battery - no connection to the +ve of the start battery

well spotted. It should go to A on the cluster. This is why new eyes are good!

Daverw

Well-Known Member

Doesn’t the alternator also need to go through the shunt or you will not pick up it’s charging

VicS

Well-Known Member

The squares at the top represent a BEP cluster of Start/House/Parallel and VSR.

I think I need to move the shunt. The installation instructions talk about 'main' battery and 'auxillary' battery. I took that to mean main=start aux=house but I suspect I have that back to front

You are missing a connection between "A" and the start battery positive........................ Or you wont charge it! ( as already noted)

The alternator negative must be connected to the other end of the shunt....... See the monitor wiring instructions ......... There must be no connection to the house battery negative other than the shunt so that all current to and from the battery negative flows through the shunt.

If the VSR is dual sensing , but I am not sure if it is, I would make the house battery the priority battery for the shorepower charger.

It's a good idea to reconfigure the BEP cluster so that the emergency paralleling switch parallels the engine and domestic circuits rather than the batteries.

As said elsewhere you show no fuses or other over current protection!

Last edited:

pmagowan

Well-Known Member

The BEP manual says to connect the charger to point A and to leave the START switch on when on shore power to charge both batteries. It is a DVSR if that makes a difference even though the wiring instructions only talk about a VSR.

VicS

Well-Known Member

The BEP manual says to connect the charger to point A and to leave the START switch on when on shore power to charge both batteries. It is a DVSR if that makes a difference even though the wiring instructions only talk about a VSR.

The D stands for "digital"

AFAICS it is not dual sensing

pmagowan

Well-Known Member

pagoda

Well-Known Member

An updated model

View attachment 68576

some questions. I have a d2 40 Volvo located about 1.5m away from the batteries. It is confusing to gauge the wire size for this ?25mm2?

Are the fuses right? Why would I wire the charger to house? Would it not charge house anyway through the VSR?

I would suggest an earth leakage circuit breaker on your mains input? Also maybe a galvanic isolator to reduce the chances of your anodes working for other boats!

pmagowan

Well-Known Member

I would suggest an earth leakage circuit breaker on your mains input? Also maybe a galvanic isolator to reduce the chances of your anodes working for other boats!

I have a saildrive so I think that is electrically isolated anyway and the throughhulls are not bonded as far as I am aware. My anodes are on the saildrive itself and, I think, the prop. New, to me, boat, so I will have to check.

The 240V supplies a single socket with a switch for the immersion and the battery charger. I will check it but I suspect it has an RCD.

I have a single flexible solar panel (32w) which I have not used yet. I might try and incorporate this into the system.

duncan99210

Well-Known Member

Does you charger have one or two outlets? If only one, the via the VSR will work. If two outlets, then one to each battery is the way to go.

pmagowan

Well-Known Member

Only one outlet. It is a ctek m200

VicS

Well-Known Member

An updated model

View attachment 68576

some questions. I have a d2 40 Volvo located about 1.5m away from the batteries. It is confusing to gauge the wire size for this ?25mm2?

Are the fuses right? Why would I wire the charger to house? Would it not charge house anyway through the VSR?

The fuses must be rated sufficiently high to carry the max expected current in the circuit ( that may be the charging current) and the wire must be heavy enough to carry that current safely. With long wire runs you may also have to consider the volts drop and increase the wire size accordingly.

It is not usual to fuse the alternator output. If the fuse blows the alternator diodes will very likely fry.

You can certainly wire the charger to the starter battery, and with the BEP DVSR that appears to be how you have to do it. The VSR will then charge the house battery when the starter battery has been charged to a specified level.

My thoughts were if the VSR was dual sensing the charger ( and solar charging) could charge the house battery as their first priority, the VSR switching in the starter battery when the house bank reaches a certain level of charge. However its not dual sensing so the starter battery will be the first priority for any charging system.

Your sail drive and engine are electrically isolated from each other. Be sure you never compromise that isolation or connect anything to the sail drive that will make a connection between it and the 12 volt system.

You incoming shore power should include an RCD and an overcurrent circuit breaker (mcb).

pmagowan

Well-Known Member

Thanks. How would I go about finding the maximum expected current for starting the engine? I suspect this is the highest current in the system so if I spec all the wires to this then I should be OK. It would be cheaper, I think, to buy 10m of wire on a spool and make up the leads from the max sizing I require. I might get one of those hydraulic lug machines and I already intend to use glued heat shrink and tinned cable/lugs. I am presumming the fuses are to protect the wiring so I can spec fuses to anything below the max current rating for the wire and above maximum expected current use.

I have read up about the protection required for saildrive isolation so I will be careful with this.

I have read up about the protection required for saildrive isolation so I will be careful with this.

dunedin

Well-Known Member

If it is a new system I would certainly design in solar power and a Bluetooth link for the battery monitor and/or solar power from the outset.

Regarding galvanic isolator, I am no expert regarding these - but our boat came with one of these from the factory, and it also has a similar engine and saildrive to yours (you seem to suggest not needed due to saildrive?)

PS Do you need to show the types and positions of battery switches in the diagram, to show for example what is and is not still connected when the start battery is switched off

Regarding galvanic isolator, I am no expert regarding these - but our boat came with one of these from the factory, and it also has a similar engine and saildrive to yours (you seem to suggest not needed due to saildrive?)

PS Do you need to show the types and positions of battery switches in the diagram, to show for example what is and is not still connected when the start battery is switched off

lw395

Well-Known Member

Indeed....

It is not usual to fuse the alternator output. If the fuse blows the alternator diodes will very likely fry.

....

Is it not normal to take the alternator output directly to a battery, do not pass go, do not collect 200milliohms?

There is a lot of 'stuff' in the alternator-house battery circuit. Any drop around this circuit equates to slower charging, if you have voltage regulation sensed at the alternator.

Some people would go as far as to get rid of the battery monitor, because all that shunt is doing is measure how badly it is reducing your charge current?

This might not be an issue if you don't care about fast charging, or you mostly charge from shore power, or you have battery sensing (doublesided) on your alternator.

pmagowan

Well-Known Member

My understanding is that a galvanic isolator is to prevent you creating a galvanic cell by joining your metal parts to another boats metal parts, through the earth cable, all immersed in sea water as an electrolyte. If your metal bits are either not in sea water or isolated from the earth cable (I.e. not bonded) then a galvanic circuit can not be created. The metal bits that matter would be through hills and the saildrive. The saildrive is isolated from earth and the throughhulls are not bonded.

I think there might be some issue with not bonding metal bits and I think in the USA it is a requirement but I can’t remember the pros.

I think there might be some issue with not bonding metal bits and I think in the USA it is a requirement but I can’t remember the pros.

VicS

Well-Known Member

Thanks. How would I go about finding the maximum expected current for starting the engine? I suspect this is the highest current in the system so if I spec all the wires to this then I should be OK. It would be cheaper, I think, to buy 10m of wire on a spool and make up the leads from the max sizing I require. I might get one of those hydraulic lug machines and I already intend to use glued heat shrink and tinned cable/lugs. I am presumming the fuses are to protect the wiring so I can spec fuses to anything below the max current rating for the wire and above maximum expected current use.

I have read up about the protection required for saildrive isolation so I will be careful with this.

I would take the size of the existing starter motor/ main battery wiring as a guide as to what is required for the main battery leads. It is a 2 kW motor which means it delivers the equivalent of 2 kW in mechanical output and will therefore draw somewhat more in electrical power during cranking. It could well draw over 500 amps in the stalled condition.

Other wiring does not have to be as heavy as the main battery leads, only needing to reflect the current it will carry in service. The workshop manual should indicate the colour codes and cross sectional areas of the engine wiring. Typically one might expect to see a range of sizes from 1mm to 2.5 mm

Other threads that may be of interest

- Replies

- 21

- Views

- 894

- Replies

- 61

- Views

- 2K