bluerm166

Well-known member

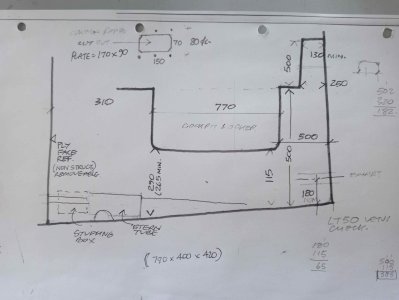

I am considering cutting out a cockpit floor locker which prevents adequate access to everything to the rear of the gearbox ,so coupling ,stuffing box,greaser,muffler,sterntube,cockpit drain outlets,gudgeon bolts etc etc.

If I look at Bosch wired tools ( e.g. bare tool ) and buy separate blades specific to the task,what is best to buy for a horizontal cutting run of 2.4 metres of say 6mm fibreglass ? Rounded cutter or 'chisel' type.

Would have direct frontal access and work on top of a glued batten - edge would be concealed anyway.

If I look at Bosch wired tools ( e.g. bare tool ) and buy separate blades specific to the task,what is best to buy for a horizontal cutting run of 2.4 metres of say 6mm fibreglass ? Rounded cutter or 'chisel' type.

Would have direct frontal access and work on top of a glued batten - edge would be concealed anyway.

Last edited: