CPD

Well-Known Member

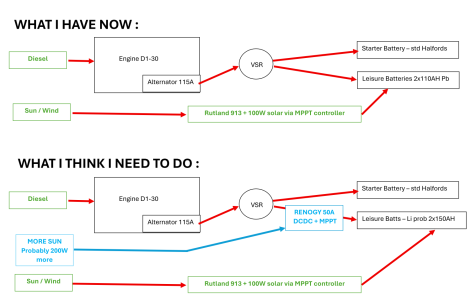

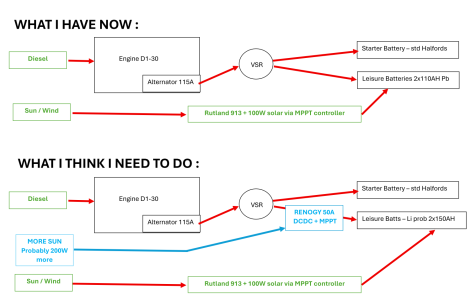

Hopefully you can see a (hugely) simplified sketch of what I currently have - a lead-acid charging system directly off the alternator using a VSR.

Also shown is what I think I need to do to upgrade to a Lithium system and at the same time add more solar.

I have become a little overwhelmed by the variety / complexity of DCDC chargers on the market, so decided to draw out my system to help clarify my thoughts.

A few points :

a. All leisure battery inputs/outputs go through a battery monitor.

b. I want to change as little of the current system as possible as it has proven itself over 10+ years.

c. This is the DCDC charger I am looking at

Questions :

1. Does it look right / safe / okay ?

2. Am I missing something / anything ?

Last comment :

I know there are many other ways of doing the same thing. I am looking for the most simple. Many thanks in anticiption of numerous comments l !!!!

l !!!!

Also shown is what I think I need to do to upgrade to a Lithium system and at the same time add more solar.

I have become a little overwhelmed by the variety / complexity of DCDC chargers on the market, so decided to draw out my system to help clarify my thoughts.

A few points :

a. All leisure battery inputs/outputs go through a battery monitor.

b. I want to change as little of the current system as possible as it has proven itself over 10+ years.

c. This is the DCDC charger I am looking at

Questions :

1. Does it look right / safe / okay ?

2. Am I missing something / anything ?

Last comment :

I know there are many other ways of doing the same thing. I am looking for the most simple. Many thanks in anticiption of numerous comments