asteven221

Well-Known Member

This something I have not done for 30 years and back then it was cars!

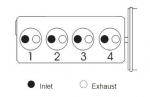

I want to check the valves on the boat and planned to do the "rule of 9" method, however I have hit on a potential issue where advice is required. I am hoping one of my fellow forumites will have the experience that I don't have and can advise me.

When I put my feeler gauge in to the gap it takes a bit of effort and once in I can move it back and forth. but the issue I have is when I remove the gauge there is a distinct click at the point the gauge comes out from the gap. I get the feeling that the valve spring is being compressed by the feeler gauge. Is that possible? Could the gap be that far out? A pal told me that there is no way I would compress the spring with the feeler gauge. but I am not so sure as I tried compressing it with my finger and it didn't too much effort to compress it slightly.

I have asked the marina to get one of their mechanics to check it out, but after 3 weeks I am still waiting!

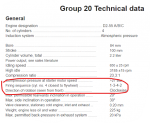

Incidentally the feeler gauge is marked 0.203 and the gap spec is actually 0.2 so could the 0.003 make a significant difference?

As always, I am grateful for any advice offered.

I want to check the valves on the boat and planned to do the "rule of 9" method, however I have hit on a potential issue where advice is required. I am hoping one of my fellow forumites will have the experience that I don't have and can advise me.

When I put my feeler gauge in to the gap it takes a bit of effort and once in I can move it back and forth. but the issue I have is when I remove the gauge there is a distinct click at the point the gauge comes out from the gap. I get the feeling that the valve spring is being compressed by the feeler gauge. Is that possible? Could the gap be that far out? A pal told me that there is no way I would compress the spring with the feeler gauge. but I am not so sure as I tried compressing it with my finger and it didn't too much effort to compress it slightly.

I have asked the marina to get one of their mechanics to check it out, but after 3 weeks I am still waiting!

Incidentally the feeler gauge is marked 0.203 and the gap spec is actually 0.2 so could the 0.003 make a significant difference?

As always, I am grateful for any advice offered.