Moodysailor

Well-Known Member

Hmm, good question. I also say no for the following reasons, but it would be a good test to do. It does raise some questions about configuration & fusing if considering emergency use.

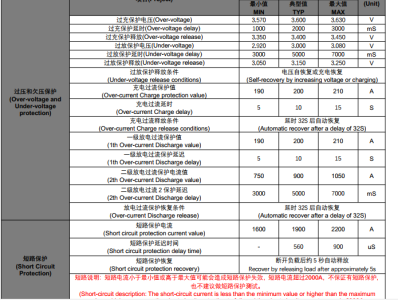

Our LiFePO4 BMS is rated at 200A. No idea if it has a peak load of not, but that indicates it won't work for a starter motor due to the inrush current. It's probably around 1kW on a big engine, and 500-700W on a typical yacht engine.

We have a 350A fuse (cable protection) on our domestic side. Even if the BMS could handle the peak load, the fuse would do it's job and blow.

My 'napkin' thoughts are that, assuming the BMS could handle the inrush, an emergency parallel system could be something as rudimentary as jumper cables as there would certainly need to be a way to bypass the fuse temporarily. If the BMS can't handle the inrush then some kind of soft-start system may be needed to help out, but this would add complexity and more failure links into an emergency system.

My takeaway - I will keep a jump pack on board in case the start battery goes flat. We have a 50hp diesel and sails, so should be able to figure something out if needed.

Our LiFePO4 BMS is rated at 200A. No idea if it has a peak load of not, but that indicates it won't work for a starter motor due to the inrush current. It's probably around 1kW on a big engine, and 500-700W on a typical yacht engine.

We have a 350A fuse (cable protection) on our domestic side. Even if the BMS could handle the peak load, the fuse would do it's job and blow.

My 'napkin' thoughts are that, assuming the BMS could handle the inrush, an emergency parallel system could be something as rudimentary as jumper cables as there would certainly need to be a way to bypass the fuse temporarily. If the BMS can't handle the inrush then some kind of soft-start system may be needed to help out, but this would add complexity and more failure links into an emergency system.

My takeaway - I will keep a jump pack on board in case the start battery goes flat. We have a 50hp diesel and sails, so should be able to figure something out if needed.