The Real Flipper

Well-Known Member

As though I don't have enough issues posted at the same time- suddenly this showed up as a priority before she goes in the water.

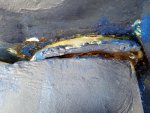

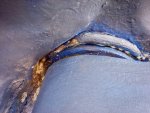

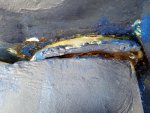

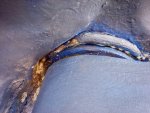

So the Rudder has an orangish, sometimes whiteish stuff that comes out of the bottom of the rudder attachment when it rains.

Two 'experts' the surveyor and an experienced guy in the boat yard said the rudder was good.

Both did a sort of inspection where they bent knees and grabbed the rudder and tried to muscle it around in different directions, then said it was good.

One said this apparently bad and apparently home repaired with some kind of silicon- rubber seal is not a problem.

Now I'm not so sure.

As usual any thoughts appreciated.

So the Rudder has an orangish, sometimes whiteish stuff that comes out of the bottom of the rudder attachment when it rains.

Two 'experts' the surveyor and an experienced guy in the boat yard said the rudder was good.

Both did a sort of inspection where they bent knees and grabbed the rudder and tried to muscle it around in different directions, then said it was good.

One said this apparently bad and apparently home repaired with some kind of silicon- rubber seal is not a problem.

Now I'm not so sure.

As usual any thoughts appreciated.