eddystone

Well-Known Member

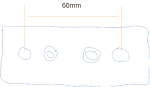

Whilst my mainsheet blocks (Main brand) are serviceable, the cam cleat on the lower block needs replacing. The hole centres are 60mm but all the possible replacements from Selden, Holt Allen, Harken etc are much too small. The nearest I can find is a Barton K cam cleat maxi with hole centres at 50mm. The s/s adjustable bracket which attaches to the bottom block has cheeks about 1.5mm thick, maybe less which are splayed outwards. How easy would it be to bend them in to gain 5mm on each side? I thought the easiest way would be to use a clamp to hold it while I attached new fitting but the elasticity of the metal would put a big strain on the fitting. I'm not sue how easily they would bend in situ. Rather not remove it as the mainsheet terminates in a splice round the becket on the top block and re-splicing is not my forte.