geem

Well-Known Member

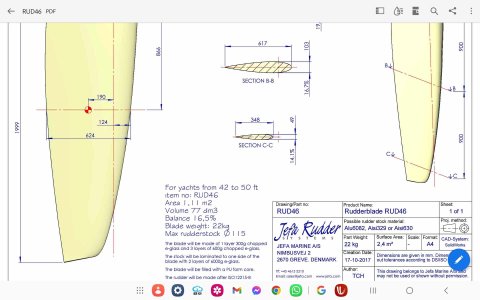

The rudder on my current boat certainly wouldn't float but some spade rudders don't have a stock that runs the full length of the blade. The idea being if you hit something, the bottom part snaps off. There may not actually be much weight in the rudder but reasonable buoyancy. Just a thoughtI doubt if my rudder would float, so surprised that the Arcona rudder might be bouyant. It would explain the excessive amount of movement that was ripping the hull apart in the area - but no water could be seen entering so the break must be some distance inside the hull. Looking at how deep the rudder is, could it have struck a submerged object in the past to start the break? No doubt the video will be studied in some depth as it is now the only record of what has happened to the rudder stock.