sj8070

Active Member

Hi all

We have a problem that we are 99% sure is air getting into fuel as whenever engines are bled they will then run for another 5 mins

have changed all filters, even had one of the fuel pump replaced - still getting the problem

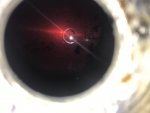

We then assumed must be an issue with the fuel tank - thinking perhaps a layer of gunge (as boat had been stood for a year without use before we bought)

Today we checked the tank (big job as carpets had to be removed, sensor removed etc) and the fuel seemed absolutely fine - see pic below

Absorleyl lost as to what it could be now - both engines connect to the tank with diff hoses so unless both engines/fuel circuits have developed the same issues it must be the tank

Only possibility we can think of is that gunge has collected up by the intakes that we can't see ?

We have a problem that we are 99% sure is air getting into fuel as whenever engines are bled they will then run for another 5 mins

have changed all filters, even had one of the fuel pump replaced - still getting the problem

We then assumed must be an issue with the fuel tank - thinking perhaps a layer of gunge (as boat had been stood for a year without use before we bought)

Today we checked the tank (big job as carpets had to be removed, sensor removed etc) and the fuel seemed absolutely fine - see pic below

Absorleyl lost as to what it could be now - both engines connect to the tank with diff hoses so unless both engines/fuel circuits have developed the same issues it must be the tank

Only possibility we can think of is that gunge has collected up by the intakes that we can't see ?