Crinan12

Well-Known Member

Hi. I am going to change my 16 year old manecraft deep sea seal. From reading other posts Volvo, tides marine or a PSS seem to be the ones people go for.

Is this a straightforward enough job? Do I need any special tools? I live 2 and a half hours away from my boat so want to make sure I have everything with me.

I was hoping the shaft unbolts easily and you just draw it out from the coupling, fit the new seal and re attach the shaft. If I'm reading other posts correctly I don't need to do any re-alignment work.

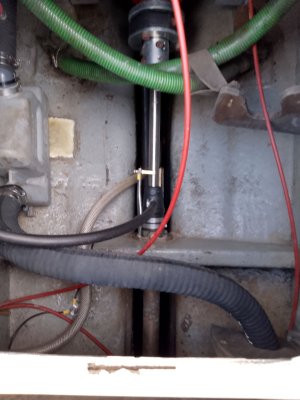

As per the photo my existing seal has 2 rubber tubes coming from it, one which terminates in the cabin (water sometimes comes out of it if engine revved hard) and the other one I think goes out of the hull above the waterline and water comes out of that as well.

I have a 1inch prop shaft.

Access to the seal is from the side and a bit of a pain but I can reach it.

Any advice about this job would be appreciated as I'm not sure about it.

Thank you

Is this a straightforward enough job? Do I need any special tools? I live 2 and a half hours away from my boat so want to make sure I have everything with me.

I was hoping the shaft unbolts easily and you just draw it out from the coupling, fit the new seal and re attach the shaft. If I'm reading other posts correctly I don't need to do any re-alignment work.

As per the photo my existing seal has 2 rubber tubes coming from it, one which terminates in the cabin (water sometimes comes out of it if engine revved hard) and the other one I think goes out of the hull above the waterline and water comes out of that as well.

I have a 1inch prop shaft.

Access to the seal is from the side and a bit of a pain but I can reach it.

Any advice about this job would be appreciated as I'm not sure about it.

Thank you

Attachments

Last edited: